Conveyors and Conveyor Equipments Design Services

Designing according to specifications of the products to be transported with the conveyor.

As result of R&D activities and engineering calculations uncover of the geometrically design of conveyor.

Providing support for complete manufacturing and assembly of the conveyor by customer requests.

Technical support on the conveyor belt selection.

Types :

- Belt Conveyors

- Roller Conveyors

- Chain Conveyors

- Helical Conveyors

- Telescopic Conveyors

- Flex Conveyors

1. Belt Conveyors :

Belt conveyors are being used for transmission, horizontal or inclined at different distances of wide variety products and general transportation purposes.

Belt selection is done according to the type of material to be conveyed. Belt selection may be preferable as; PVC, polyurethane, rubber, wicker belt type. Belt conveyors are suitable for the carriage for boxed, bulk and packaged products. Utilization capacity is highly variable.

Conveyor feet group and the frame is usually made of steel construction with electrostatic-powder coating or aluminum.

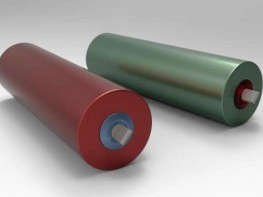

2. Roller Conveyors :

Roller conveyors may be used for in a wide range to transfer materials conveyance on assembly lines. Part of goods, square or cylindrical goods, boxed, packaged products can be transfer easily with roller conveyors. Products are transmitted with conveyor rollers space properly on the frame. Roller conveyors are two types as driven and idle rollers according to working forms.

Roller frequency is determined according to roller diameters and the type of product to be moved.

Galvanized, rubber or PVC coated rollers are designed according to customer usage.

3. Chain Conveyors :

Chain conveyors are used usually in transportation of pallets and specific applications. The design of the conveyor chain system is highly flexible due to the ability to move. Complicated elevator systems are used in many fields like carriage of slip dresses.

Bean Type Chain Conveyors :

Bean type chain conveyors are manufactured from acetal, inox bean chains or wicker belts to transport all kind boxed and packaged products. They especially used in applications requiring corrosion resistance like food industry. These types conveyors are usually narrower. However width is generally adjustable. This system is used of special processing as capping, barcoding and ranking.

Conveyor frame is made from aluminum, electrostatic powder coated steel construction or inox material.

4. Helical Conveyors :

Helical conveyors are the most economical solution for transportation by electric power. Because of high investment costs, they are not preferred as application in long distances. But just the opposite their operating costs are lower than the other types.

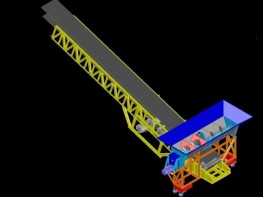

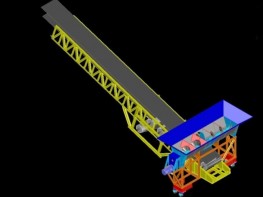

5. Telescopic Conveyors :

Telescopic conveyors are used for the loading and unloading materials into vehicles such as trucks quickly and easily. This types conveyors reduces number of staff with easy handling and design. The most prominent feature of telescopic conveyor is conveyor length can be changed while working. Telescopic conveyors may be manufactured from PVC belts or rollers. Conveyor height is adjustable with a hydraulic unit.

6. Flex Conveyors :

Flex conveyors are made from plastic or steel tube rollers. Scissors-type conveyors are running in the open and close processes. These type provides high flexibility in loading and unloading operations for boxed and packaged materials.

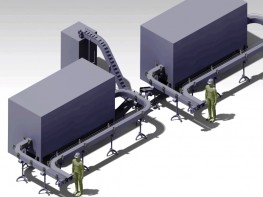

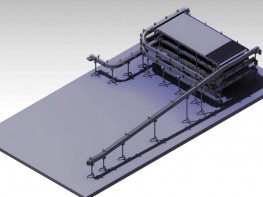

Conveyor Designs

Conveyor Designs

Conveyor Designs